Project: Chiller & Tube Sheet

Industry: Casinos and Convention Centers

Substrate: Carbon Steel

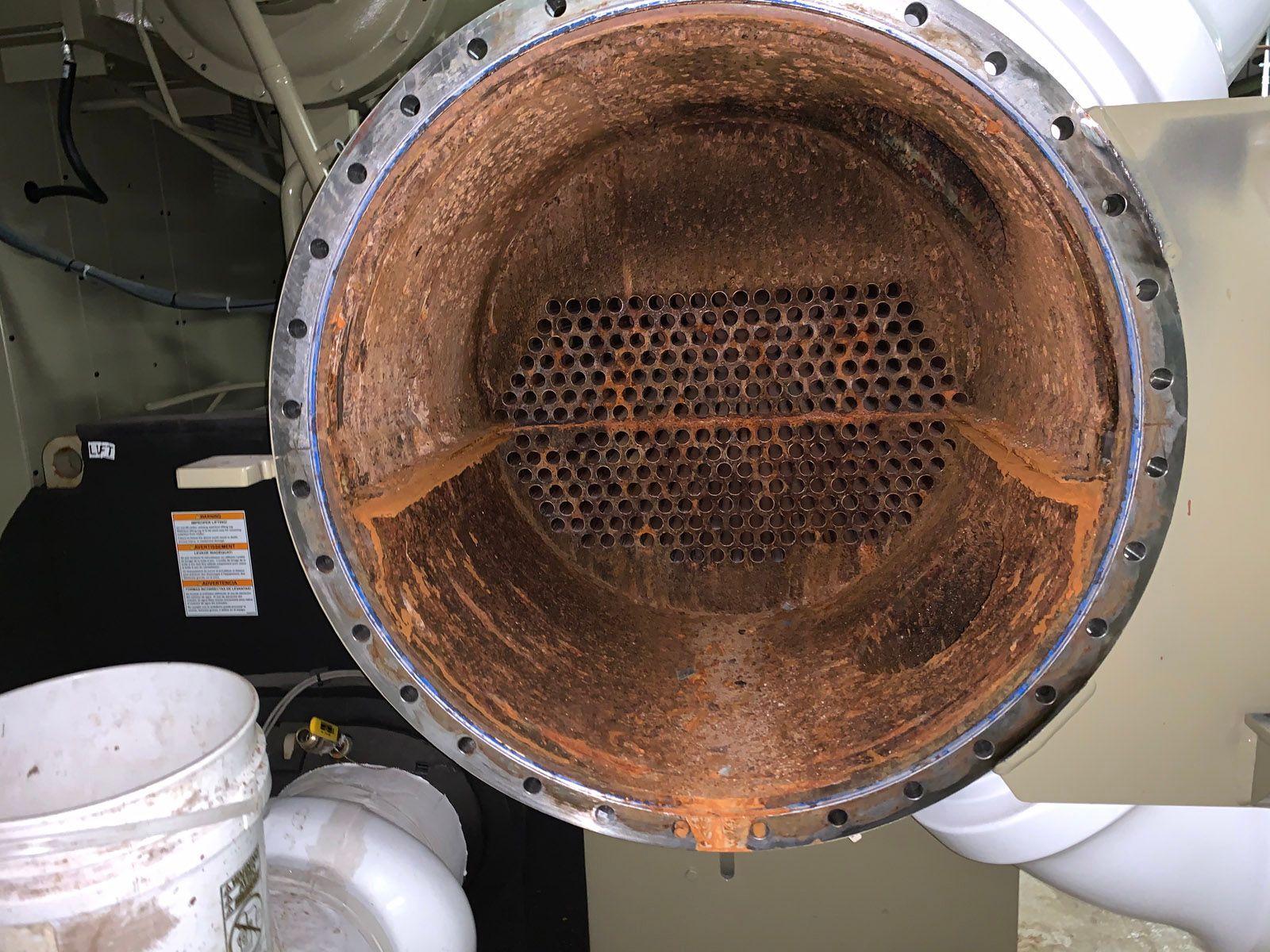

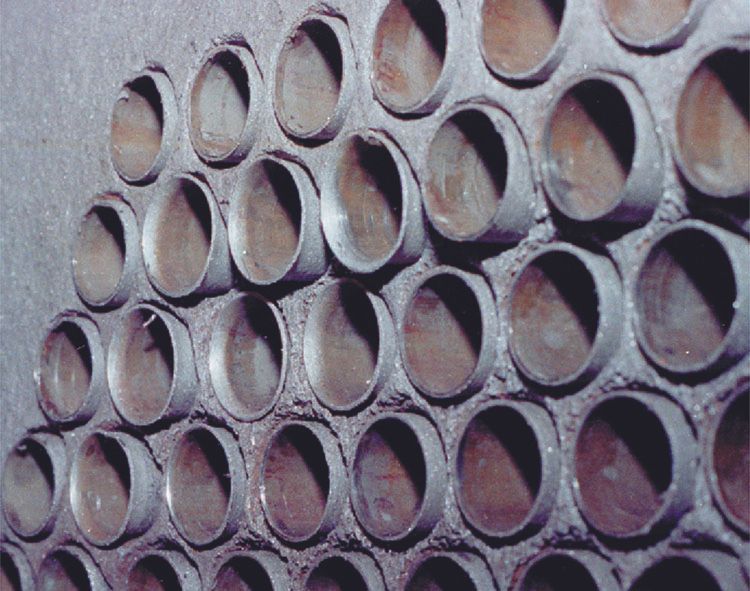

Problem: The Customer was experiencing rising electrical costs because their HVAC Chiller was losing efficiency caused by corrosion, partially clogged tubes, and a leaking Tube Sheet.

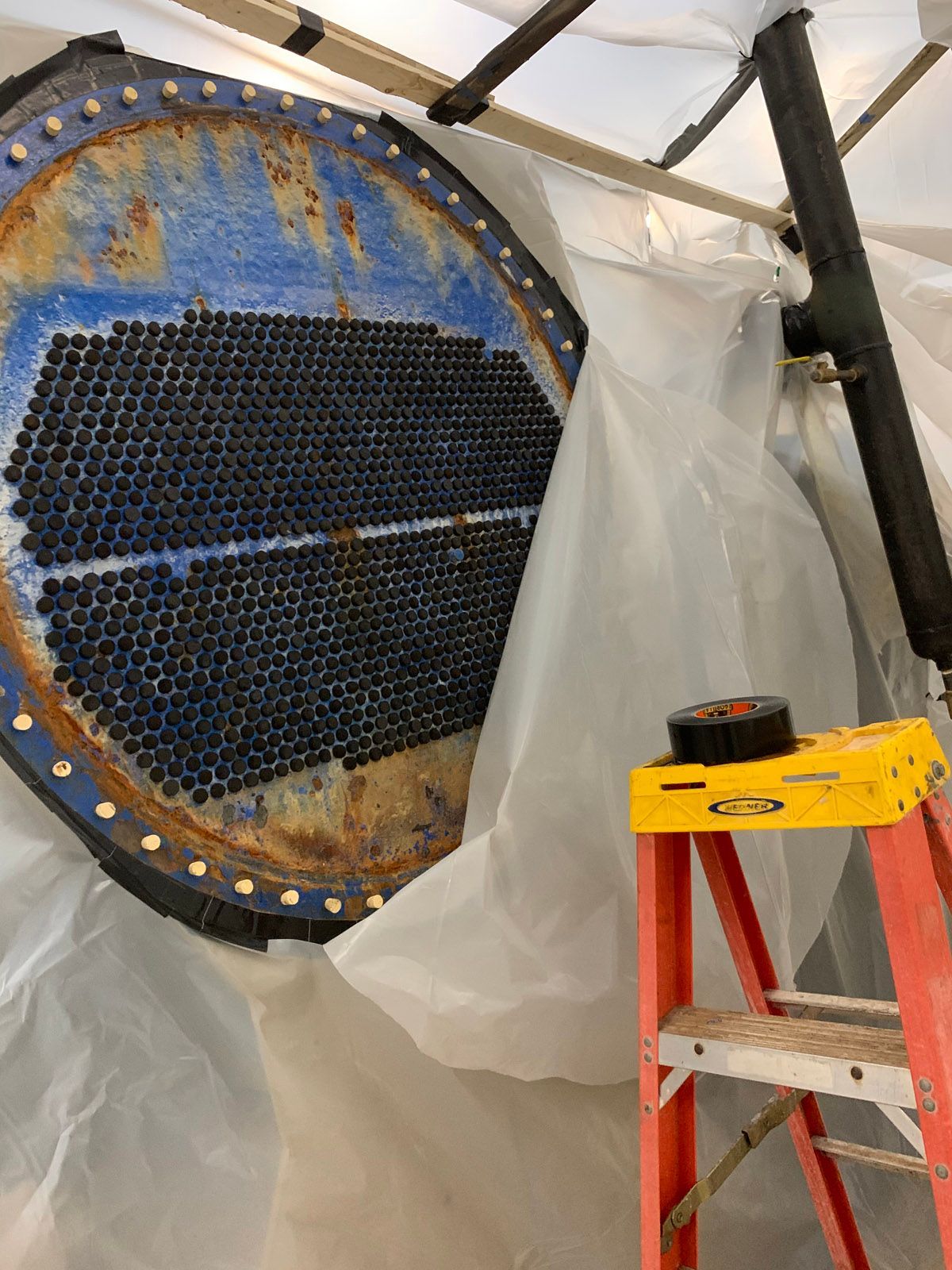

Solution: The Chiller was shut down and the tubes were cleaned out by our customer's maintenance team. Advanced Specialty Coatings then came in to repair the damage from corrosion and erosion. Our team built a containment area to isolate the asset from the abrasive blast necessary to properly create a profile to specifications in preparation for the repairs. We then repaired the damaged areas with using xxxx epoxy. Lastly, we applied a protective coating to the Tube Sheets, Water Box and Covers ensuring long-lasting wear and durability.

Result:

Application is fast for reduced downtime and cost effective compared to lost efficiency or replacement of damaged machinery. Results are extremely durable for long-term service.